In 2004, DARPA offered $1 million to anyone who could build an autonomous vehicle that could navigate a rugged 142-mile course through the desert. None finished, and most barely made it past the starting line. Yet, this failure seeded a vibrant new research community. Just 18 months later, five vehicles were able to complete the course, laying the foundation for today’s autonomous vehicle industry. In fact, when you’re hailing a Waymo driverless taxi today, you’re riding on the legacy of those dusty desert sprints. DARPA’s gamble proved that high-visibility competitions–even those that begin in failure–can catalyze extraordinary progress when the challenge is bold and the community shows up.

Role of Community Benchmarks in Protein Design: From Structure Prediction to Function Design

For computational protein design, protein structure prediction represented the last grand challenge. Until the AI powered, Nobel Prize winning AlphaFold2 came, determining protein structure was a time-consuming process that was done using laborious experimental techniques like X-ray crystallography. CASP (Critical Assessment of Protein Structure Prediction) is a community benchmarking competition that has been challenging the community to solve the grand challenge of protein structure prediction every two years, since 1994. CASP does this by providing a neutral platform to assess the power of computational structure prediction models to match a yet to be publicly available, experimentally determined novel protein structure. It provides a uniform evaluation criteria to assess the predictive power of a given computational model, called the global distance test total score (GDT-TS), a score of 90 means that the model’s prediction is indistinguishable from experimentally observed protein structure. As the number and complexity of protein structures in the protein data bank (PDB) increased, the CASP challenged the participants to predict newer and more complex protein structures. For many years no team was able to have a score of 90, until 2020 , when Google-Deep Mind’s AlphaFold2 was able to achieve a GDT-TS score in the high 90s.

The next grand challenge in computational protein design is protein function prediction and design. While predicting static protein structure is an important step in being able to design novel proteins, proteins are inherently dynamic molecules, and this dynamic nature is what affords them their unique functional ability. An enzyme in order to carry out its function has to bind to its correct substrate, catalyze the chemical conversion of the substrate to the product, and release the product into the solution. Being able to predict and design protein function is quite challenging, as implicit in this is the ability to predict and design these dynamic changes. As newer AI/ML models for protein function design develop, there is a need for a CASP style community benchmarking competition. Deploying such competitions is quite challenging. Unlike structure prediction which relies on a large database of protein structures. Furthermore, most real-world protein design and engineering requires being able to optimize for multiple, often unrelated properties. For example, designing a detergent enzyme that breaks down tough grime on clothes requires it to be active in detergent, high salt, oxidizing agents, and temperatures above 60C for real-world protein design problems.

Energized by the success of CASP, other competitions like Adaptyv Bio’s binder challenge, CACHE, AIntibody, BioML’s Bits to Binders, and the Rosetta Design Games have created public testbeds for modeling tools. Most of these competitions focus on structure or binding, two properties that are increasingly within the wheelhouse of modern design tools. There is a need for community benchmarking competitions for designing functional enzymes for real-world applications.

PETase Engineering: A Testing Ground for AI-based Protein Design Methods to Solve Real-World Problem

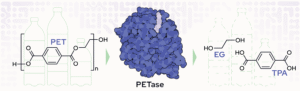

There are countless enzymes that test the limits of protein design. Among them, PETases stand out for their real-world relevance in solving plastic pollution. These enzymes break down polyethylene terephthalate (PET), a major component of plastic bottles, packaging, and textiles, into reusable monomers, which can be reassembled into new, high-quality products. While traditional recycling downgrades plastics into lower-performance materials, enzymatic recycling offers a path to true circularity–where plastic retains its quality and value. A scalable PETase-based solution would reduce landfill waste, lower demand for virgin petroleum, and shift manufacturing toward regenerative practices. In 2024, global plastic production hit 410 million metric tons, and may triple by 2060. Yet, only 10% of plastic is truly recycled; most ends up in landfills or is incinerated. Plastic waste leaches endocrine-disrupting chemicals such as phthalates and BPA into waterways, harms marine species, and fragments into the microplastics now ubiquitous in the environment and in our bodies.

This is a valuable problem to solve, and it’s only the beginning. The same strategies used here could be applied to other urgent environmental challenges: designing enzymes to upcycle additional plastics, degrade persistent pollutants and forever chemicals, or capture greenhouse gases like carbon dioxide and methane. Protein design has the potential to become a pillar of climate technology. To realize that vision, the field needs experimental benchmarks that validate progress, reveal failure modes, and allow researchers to iterate together. That’s what this competition (and future ones) are meant to provide.

PETases have been studied since the early 2010s but still perform poorly under industrially-relevant conditions. PET is a dense and tangled polymer made up of repeating units, like beads on a string. The enzyme breaks these units apart one at a time, but must first access the tangled strand. Heating the plastic helps, but most PETases stop working above 30 °C. They are also sensitive to their environmental conditions, including pH and the presence of chemical impurities that are often present in post-consumer plastic. These constraints limit their real-world applicability.

Progress in PETase engineering has followed the evolution of protein design itself. Rational design introduced stabilizing loops. Directed evolution produced HotPETase, which tolerates higher heat. Machine learning yielded enzymes like FAST-PETase, active across broader pH and temperature ranges, yet all of these approaches build on natural scaffolds. Their performance is limited by what evolution has already explored. de novo PETase design—building an enzyme from scratch—remains an open challenge.

Unlike previous isolated efforts, we hope there is a need for a benchmark that yields head-to-head comparisons across design methods under consistent conditions. It creates the first shared dataset for PETase function, expression, and design performance—critical for method validation and model generalization.

Inside The 2025 Protein Engineering Tournament

Align’s tournament is poised to push past today’s limitations. It welcomes teams from a wide range of research backgrounds and provides a level playing field through standardized testing and public benchmarking. Results from Align’s 2023 amylase competition were published in PROTEINS, the same peer-reviewed journal that hosts CASP outcomes. This set a precedent: teams not only competed but also shared their approaches, helping to build a collaborative culture that underpins today’s benchmarking efforts. This year’s PETase competition continues this model, enabling participants to publish, collaborate, and collectively raise the bar for enzyme design.

PETase assays are technically challenging because plastic is a solid substrate—unlike the soluble molecules most enzymes act on. Accurate quantification requires chromatography or mass spectrometry to detect breakdown products. Some proxies use soluble analogs to approximate degradation and allow higher-throughput screening. Each method involves tradeoffs in speed, sensitivity, and real-world relevance. Rather than accept the limitations of either assay, Align will use both—a strategy that improves validation and comparability. Detailed protocols will be published alongside the dataset to support reproducibility and enable follow-on research.

Finally, one of the biggest bottlenecks in enzyme engineering is expression. Many computationally promising designs never make it past the lab bench and into industrial applications because cells or cell free systems can’t produce these proteins efficiently. Protein expression is a material barrier to real-world applications. To tackle this, Align also measures expression in a model host organism, and in a cell free protein synthesis system. Every designed protein is assessed on both fronts, ensuring that top-performing designs are not only functional, but also viable for real-world deployment.

What’s at Stake and Who Should Join

This year, the Align Foundation is launching an ambitious challenge to accelerate enzyme engineering for climate solutions. The 2025 Align Protein Engineering Tournament invites AI researchers and protein designers to build better variants of PETase, a plastic-degrading enzyme with the potential to close the loop on polymer recycling. Engineered PETases could transform plastic waste management at scale and serve as a blueprint for how biology and AI can accelerate climate solutions. The competition provides centralized testing and public benchmarks, establishing a proving ground for the next generation of enzyme design models.

The 2025 competition is already drawing top-tier participants, including leaders in the field from academia and industry. It offers a front-row seat to the future of AI-driven protein design, highlighting which models hold up under experimental scrutiny, and where new strategies are still needed. For participants, the competition provides a rare opportunity to test models in the lab on a high-impact protein.

Like DARPA’s Grand Challenge, this competition plants a flag in a new frontier. Over the next nine months, it will focus some of the brightest minds in biology and AI on a shared environmental problem. If the top teams succeed, we’ll get enzymes that help build a circular plastic economy. Regardless, we’ll still map the terrain—learning fundamental scientific principles, where current models stall, where the road gets rough, and how to go further next time.

If you’re working at the intersection of AI and biology, register your team, bring your peers, and help define what’s possible when design meets the real world.